17th August 2018 Novel sensors could enable smarter textiles A team of engineers at the University of Delaware is developing next-generation smart textiles by creating flexible carbon nanotube composite coatings on a wide range of fibres, including cotton, nylon and wool. Their discovery is reported in the journal ACS Sensors, where they demonstrate the ability to measure an exceptionally wide range of pressure – from the slightest touch of a fingertip, to the force of being driven over by a forklift. Fabric coated with this sensing technology could be used in future "smart garments" where the sensors are slipped into the soles of shoes or stitched into clothes for detecting human motion. Carbon nanotubes provide impressive sensing capability for this light, flexible, breathable fabric coating. When the material is squeezed, large electrical changes in the fabric are easily measured. Nerve-like, electrically conductive, nanocomposite coatings are created on the fibres using a process called electrophoretic deposition (EPD) of polyethyleneimine functionalised carbon nanotubes.

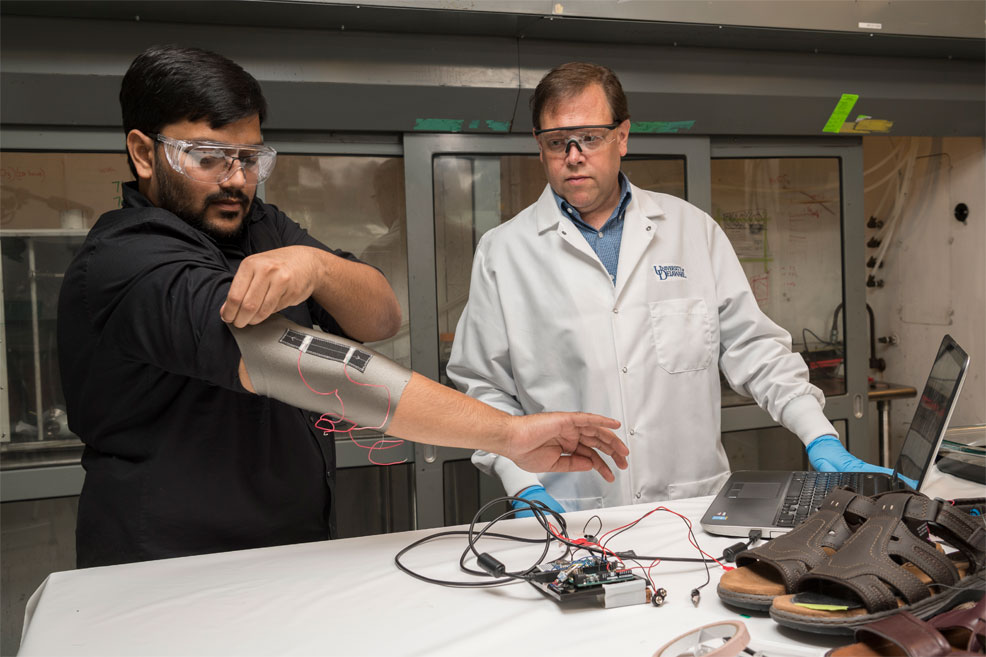

"As a sensor, it's very sensitive to forces – ranging from touch to tons," explains Erik Thostenson, from the Departments of Mechanical Engineering and Materials Science and Engineering. "The films act much like a dye that adds electrical sensing functionality. The EPD process developed in my lab creates this very uniform nanocomposite coating that is strongly bonded to the surface of the fibre. The process is industrially scalable for future applications." Now, researchers can add these sensors to fabric in a way that is superior to current methods for making smart textiles. Existing techniques, such as plating fibres with metal or knitting fibre and metal strands together, can decrease the comfort and durability of fabrics. The nanocomposite coating developed by Thostenson's group is flexible and pleasant to the touch and has been tested on a range of natural and synthetic fibres, including Kevlar, wool, nylon, Spandex and polyester. The coatings are just 250 to 750 nanometres thick – about 0.25 to 0.75% as thick as a piece of paper – and would only add about a gram of weight to a typical shoe or garment. What's more, the materials used to make the sensor coating are inexpensive and relatively eco-friendly, since they can be processed at room temperature with water as a solvent. One potential application of the sensor-coated fabric is to measure forces on people's feet as they walk. This data could help clinicians assess imbalances after injury or help to prevent sports injuries. Thostenson's team is collaborating with Jill Higginson, director of the Neuromuscular Biomechanics Lab at UD, as part of a pilot project. Their goal is to see how these sensors, when embedded in footwear, compare to biomechanical lab techniques such as instrumented treadmills and motion capture. During lab testing, people know they are being watched, but outside the lab, behaviour may be different: "One of our ideas is that we could utilise these novel textiles outside of a laboratory setting – walking down the street, at home, wherever," explains Thostenson.

"Because the low-cost sensor is thin and flexible, the possibility exists to create custom footwear and other garments with integrated electronics to store data during their day-to-day lives," said Sagar Doshi, a doctoral student in mechanical engineering at UD and lead author on the paper. "This data could be analysed later by researchers or therapists to assess performance and ultimately bring down the cost of healthcare." Doshi worked on making the sensors – optimising their sensitivity, testing their mechanical properties and integrating them into shoes. He has worn the sensors in preliminary tests, and so far, they collect data that compares with that collected by a force plate, a laboratory device that typically costs thousands of dollars. This technology could also be promising for sports medicine applications, post-surgical recovery, and for assessing movement disorders in paediatric populations. "It can be challenging to collect movement data in children over a period of time and in a realistic context," said Robert Akins, Director of the Center for Pediatric Clinical Research and Development at the Nemours Alfred I. duPont Hospital for Children in Wilmington and affiliated professor of materials science and engineering, biomedical engineering and biological sciences at UD. "Thin, flexible, highly sensitive sensors like these could help physical therapists and doctors assess a child's mobility remotely, meaning that clinicians could collect more data, and possibly better data, in a cost-effective way that requires fewer visits to the clinic than current methods do." "We've been working with carbon nanotubes and nanotube-based composite sensors for a long time," said Thostenson, who is affiliated faculty at UD's Center for Composite Materials (UD-CCM). Working with researchers in civil engineering, his group has pioneered the development of flexible nanotube sensors to help detect cracks in bridges and other large-scale structures. "One of the things that has always intrigued me about composites is that we design them at varying lengths of scale – all the way from the macroscopic part geometries, an airplane or an airplane wing or part of a car, to the fabric structure or fibre level. Then, the nanoscale reinforcements like carbon nanotubes and graphene give us another level to tailor the material structural and functional properties. Although our research may be fundamental, there is always an eye towards applications. UD-CCM has a long history of translating fundamental research discoveries in the laboratory to commercial products."

Comments »

If you enjoyed this article, please consider sharing it:

|