28th December 2018 Revolutionary new bioplastics could help conserve oceans, land and fresh water Researchers at Tel Aviv University have described a new process to make truly sustainable bioplastics, which degrade easily and don't require land or fresh water to produce.

A new study, published in the January 2019 issue of Bioresource Technology, describes a potentially revolutionary method to make bioplastic polymers that don't require land or fresh water – resources that are increasingly scarce around the world. The polymer is derived from microorganisms that feed on seaweed. It is biodegradable, produces zero toxic waste and recycles into organic waste. Plastic now accounts for 90% of pollutants in our oceans, with up to 13 million metric tons being added each year. It has been estimated that plastic pollution will exceed fish biomass by 2050, based on current trends, with grave consequences for the food chain and ultimately consumption by humans. Likewise, less than 5% of seabirds had plastics in their stomach during the early 1960s – a figure that now exceeds 90% – and it is predicted that 99% of seabird species will be affected by 2050. Yet there are few comparable, environmentally friendly alternatives to the material. "Plastics take hundreds of years to decay," says Dr. Alexander Golberg, from Tel Aviv University's Porter School of Environmental and Earth Sciences. "So bottles, packaging and bags create plastic 'continents' in the oceans, endanger animals and pollute the environment. Plastic is also produced from petroleum products, which has an industrial process that releases chemical contaminants as a by-product. "A partial solution to the plastic epidemic is bioplastics, which don't use petroleum and degrade quickly. But bioplastics also have an environmental price: to grow the plants or the bacteria to make the plastic requires fertile soil and fresh water. Our new process produces 'plastic' from marine microorganisms that completely recycle into organic waste."

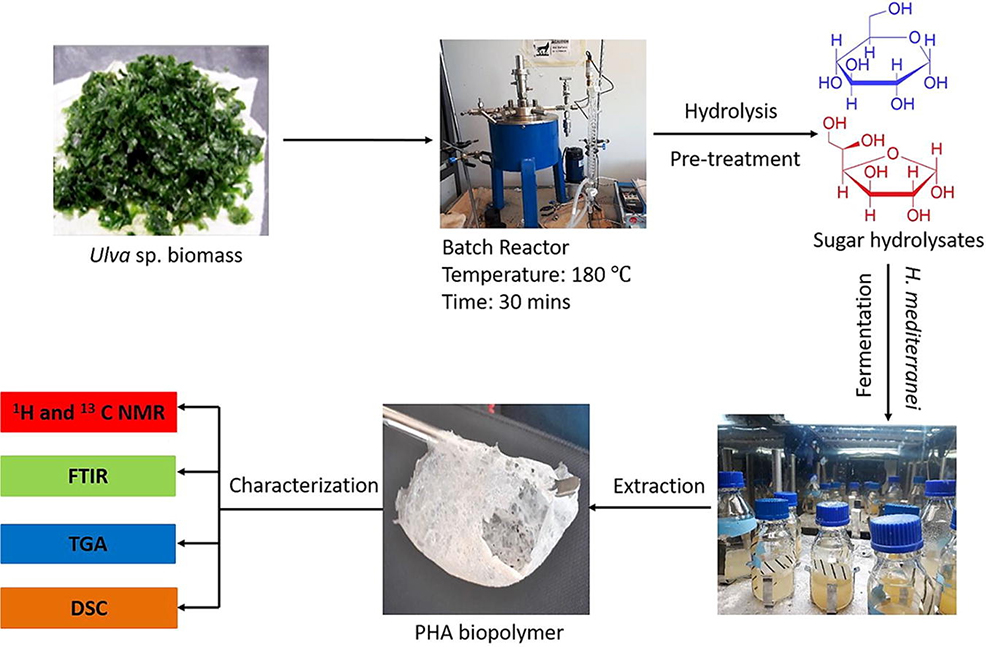

The team harnessed microorganisms that feed on seaweed to produce a bioplastic polymer called polyhydroxyalkanoate (PHA): "Our raw material was multicellular seaweed, cultivated in the sea," Dr. Golberg explains. "These algae were eaten by single-celled microorganisms, which also grow in very salty water and produce a polymer that can be used to make bioplastic. "There are already factories that produce this type of bioplastic in commercial quantities. However, they use plants that require agricultural land and fresh water. The process we propose will enable countries with a shortage of fresh water – such as Israel, China and India – to switch from petroleum-derived plastics to biodegradable plastics." This new study could revolutionise the world's efforts to clean the oceans, without affecting arable land and without using fresh water, according to Golberg. "Plastic from fossil sources is one of the most polluting factors in the oceans," he says. "We have proved it is possible to produce bioplastic completely based on marine resources in a process that is friendly both to the environment and to its residents. "We are now conducting basic research to find the best bacteria and algae that would be most suitable for producing polymers for bioplastics with different properties," he concludes.

Comments »

If you enjoyed this article, please consider sharing it:

|