1st July 2021 Volvo to use fossil-free steel in cars by 2026 Swedish companies Volvo and SSAB have announced a collaboration to jointly explore the development of fossil-free, high quality steel for use in the automotive industry.

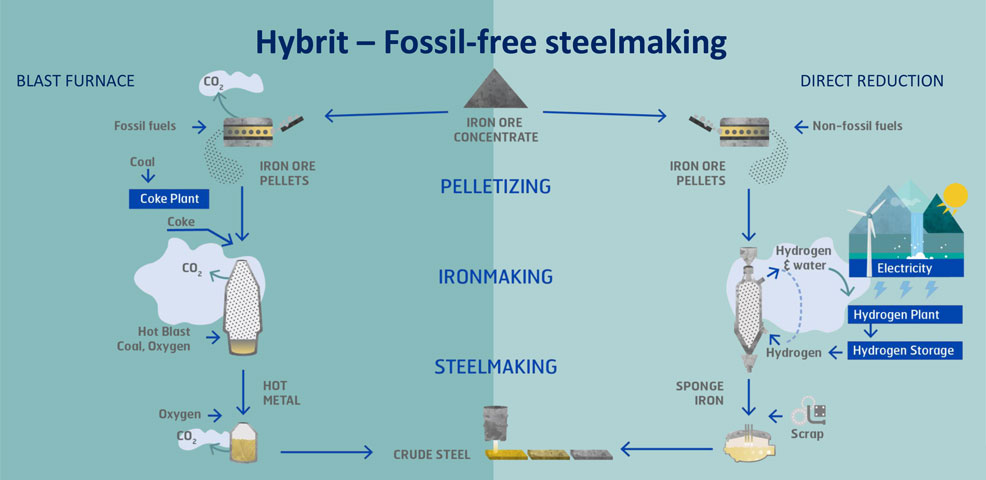

Volvo is the first car maker to work with SSAB and its HYBRIT initiative (Hydrogen Breakthrough Ironmaking Technology), the steel industry's most ambitious and advanced projects in fossil-free steel development. SSAB established HYBRIT alongside iron ore producer LKAB and energy firm Vattenfall. It aims to replace coking coal, traditionally needed for iron ore-based steelmaking, with fossil-free electricity and hydrogen. The result is expected to be the world's first fossil-free steelmaking technology, with virtually no carbon footprint. As part of the collaboration, Volvo will be the first car maker to secure SSAB steel made with hydrogen-reduced iron from HYBRIT's pilot plant in Luleå, Sweden, pictured above. This steel will be used for testing purposes and may then be demonstrated in a concept car. In 2026, SSAB will begin supplying the market with fossil-free steel at a commercial scale. Volvo aims to be the first car maker to use this steel for its own production cars. The traditional way of producing steel involves removing oxygen from the iron ore, using carbon and coke in a blast furnace. The raw iron that is tapped from the blast furnace is liquid and moves on in that form through the process until it is poured out as ingots. By contrast, the HYBRIT process involves removing the oxygen from the iron ore using hydrogen. The reduction occurs at a lower temperature and the result is so-called sponge iron. This can then be smelted in an electric arc furnace, powered by renewables. The waste product is water, as opposed to carbon dioxide. "We are building an entirely fossil-free value chain, all the way to the end customer," said Martin Lindqvist, President and CEO at SSAB. "Our breakthrough technology has virtually no carbon footprint and will help strengthen our customers' competitiveness. Together with Volvo Cars, we aim to develop fossil-free steel products for the cars of the future."

Globally, steel production has more than doubled since the year 2000. It now accounts for around 7% of global direct carbon emissions, due to the industry being dominated by iron ore-based steel making technology using blast furnaces that depend on coking coal. For Volvo, the CO2 emissions related to steel and iron for its cars amount to 35% in a traditionally powered car and 20% in a fully electric car of the total CO2 emissions from the material and production of components going into the car. Volvo aims to be a fully electric car brand by 2030, with only pure electric cars in its line-up. Yet the company's plan goes beyond addressing tailpipe emissions through all-out electrification – it also seeks to tackle carbon emissions in the supply chain and through the recycling and reuse of materials. In the short term, these and other steps aim to reduce the life cycle carbon footprint per car by 40% by 2025 (compared to 2018). The longer-term goal is for Volvo to become a climate neutral company by 2040. "As we continuously reduce our total carbon footprint, we know that steel is a major area for further progress," said Håkan Samuelsson, Chief Executive at Volvo. "The collaboration with SSAB on fossil-free steel development could give significant emission reductions in our supply chain."

Comments »

If you enjoyed this article, please consider sharing it:

|