29th April 2022 Ultra-pure diamond could store 25 exabytes of data Engineers have developed a way to mass-produce diamond wafers that could store the equivalent of a billion Blu-ray disks on a single device.

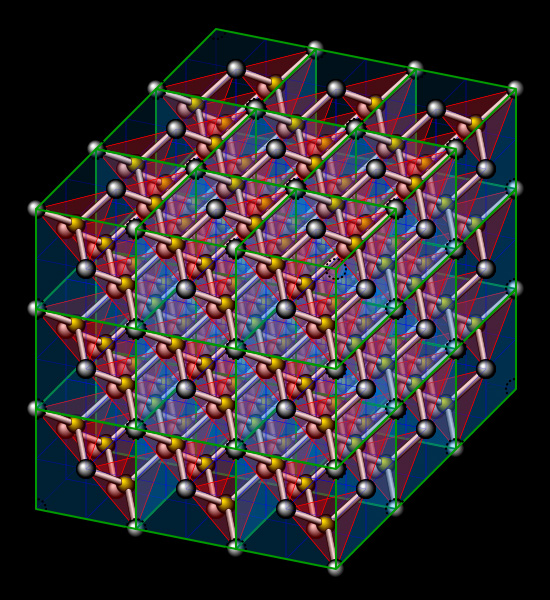

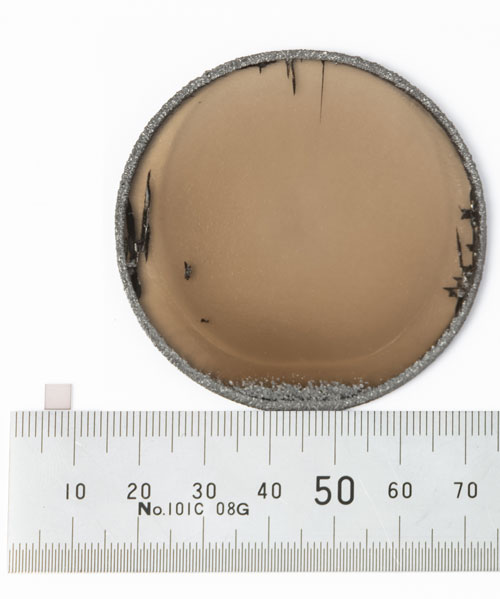

The world's hardest gemstone, diamond, has major potential as a storage medium. With extreme density and durability, excellent thermal conductivity and electrical resistance/conductivity, chemical stability, along with transmittance of a broad wavelength spectrum from ultraviolet to infrared, it offers some of the best physical properties of all known materials. However, previous attempts to exploit these qualities for storage applications in the emerging field of quantum computing have been unsuccessful, due to a combination of impurities within the material and a lack of scalability. Japanese researchers have now achieved a breakthrough. A team from Adamant Namiki Precision Jewel Co., collaborating with researchers at Saga University in Kyushu, Japan, just announced a new technique to produce diamond wafers at both a larger scale and with ultra-high purity. In September 2021, the same team produced a 55mm (2-inch) diameter wafer, much larger than the 4×4mm crystals available before. Their method used nitrogen gas to achieve a high growth rate suitable for mass production. But it left several thousand parts per billion (ppb) of impurities, meaning it would be unsuitable for quantum computing. A new, improved technique, announced this month, has overcome this issue. It nearly eliminates nitrogen contamination during the crystal growth process, resulting in ultra-high purity, reducing the impurities from several thousand to a maximum of just 3 ppb. The team also developed "step flow growth" technology to ensure the crystal grows laterally, as opposed to the vertical growth of previous methods. This leads to improved quality by spreading the strain horizontally, which minimises cracking of the diamond crystal.

The latest version pictured here may appear rough looking, but it represents a major advancement in technology. Such is the difference in scale, you could almost miss the earlier white crystal included as a size comparison on the left. Once a diamond crystal is fully grown, tiny defects known as nitrogen-vacancy centres can be exploited to hold data in the form of superconducting quantum bits (qubits). A nitrogen-vacancy centre consists of a nitrogen atom and a corresponding vacancy in the diamond lattice. This can form a minute magnetic force and function as high performance quantum memory at the atomic level. Quantum computers will be vastly more powerful and many orders of magnitude faster than traditional computers, since they work with multiple states, as opposed to binary "0" and "1" values. The wafer developed here is large enough and now has sufficiently high purity for use in quantum computers. A diamond layer contains around 3 x 1015 atoms/cm². Given the scale achieved by the Japanese researchers here, they estimate that a fully functional version of their wafer could store up to 25 exabytes of data, the equivalent of one billion Blu-Ray disks. For another perspective, that is greater than the entire world's mobile data traffic for a typical month in 2018. It would also be 73,000 times more than the 5D data storage device we reported on in 2016. This sort of capacity might seem like overkill. But the world's data continues to grow exponentially, while the information required for quantum computers to function effectively and make valuable discoveries will mean such devices are needed in the near future. The new wafer has been named KENZAN Diamond. It will be presented at the International Conference on Compound Semiconductor Manufacturing Technology held in California from 9th-12th May. Adamant Namiki Precision Jewel Co. now intends to combine their new process with peripheral technology, including a polishing system, in preparation for commercial release in 2023.

Comments »

If you enjoyed this article, please consider sharing it:

|