17th December 2022 Scientists find material with highest toughness ever recorded Scientists in the U.S. have measured the highest toughness ever recorded, of any material, while investigating a metallic alloy made from chromium, cobalt, and nickel (CrCoNi).

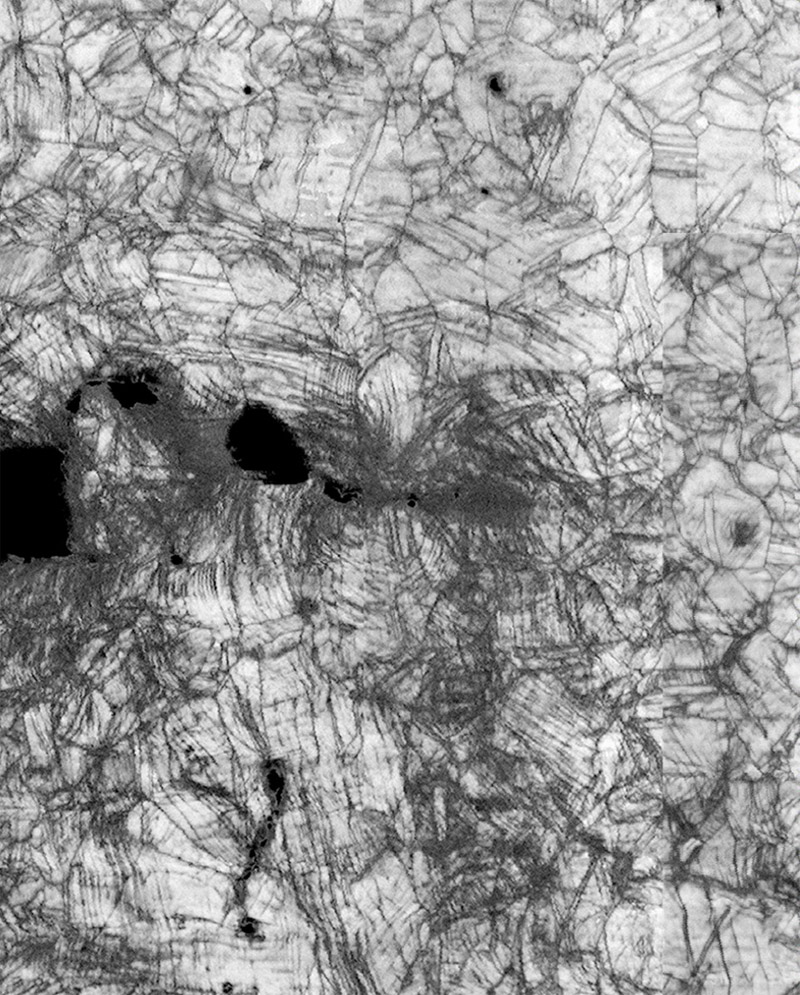

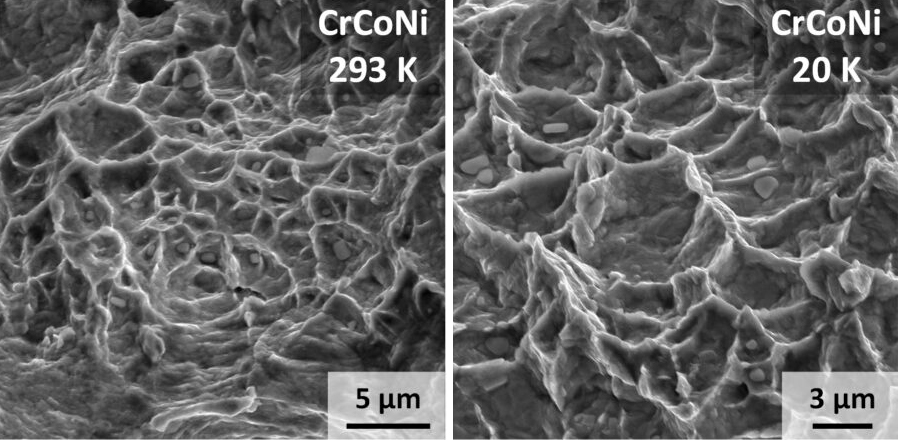

Pictured above is a microscopy-generated image of the newly discovered CrCoNi alloy during stress testing. A fracture, viewed at nanometre scale, can be seen propagating from left to right. Not only is the metal extremely ductile – which, in materials science, means highly malleable – and extremely strong (meaning it resists permanent deformation), its strength and ductility actually improve as it gets colder. This runs counter to most other materials in existence. A team, led by researchers from Lawrence Berkeley National Laboratory (Berkeley Lab) and Oak Ridge National Laboratory, have published a study describing their record-breaking findings in the journal Science. Today, all of the alloys used for industrial purposes contain a high proportion of one element, with lower amounts of additional elements added. By contrast, CrCoNi belongs to a subset of a class of metals called high entropy alloys (HEAs), which are made from an equal mix of each constituent element. This "balanced" atomic configuration appears to confer some of these materials with an extraordinarily high combination of strength and ductility when under extreme stress, which together make up what is termed "toughness." HEAs have been a hot area of research since they were first developed about 20 years ago, but the technology required to push the materials to their limits in extreme tests was not available until recently.

"The toughness of this material near liquid helium temperatures (20 kelvin, –253°C) is as high as 500 megapascals square root metres," said Robert Ritchie, Professor of Mechanical Engineering at Berkeley and study co-author. "In the same units, the toughness of a piece of silicon is one, the aluminium airframe in passenger airplanes is about 35, and the toughness of some of the best steels is around 100. So, 500, it's a staggering number." The team's new findings, alongside other recent work on HEAs, may force the materials science community to reconsider long-held notions about how physical characteristics give rise to performance. "It's amusing, because metallurgists say that the structure of a material defines its properties, but the structure of the CrCoNi is the simplest you can imagine – it's just grains," explained Ritchie. "However, when you deform it, the structure becomes very complicated, and this shift helps explain its exceptional resistance to fracture," added co-author Andrew Minor, director of the National Center of Electron Microscopy facility at Berkeley Lab and Professor of Materials Science and Engineering. "We were able to visualise this unexpected transformation due to the development of fast electron detectors in our microscopes, which allow us to discern between different types of crystals and quantify the defects inside them at the resolution of a single nanometre – the width of just a few atoms – which as it turns out, is about the size of the defects in deformed CrCoNi structure." Now that the inner workings of the CrCoNi alloy are better understood, it and other HEAs are one step closer to adoption for special applications. Though these materials are expensive to create, the researchers foresee uses in situations where environmental extremes could destroy standard metallic alloys, such as in the frigid temperatures of deep space. The team at Oak Ridge is also investigating how alloys made of more abundant and less expensive elements – there is a global shortage of cobalt and nickel due to their demand in the battery industry – could be coaxed into having similar properties. While the progress is exciting, Professor Ritchie warns that real-world use could still be a long way off, and for good reason. "When you are flying on an airplane, would you like to know that what saves you from falling 40,000 feet is an airframe alloy that was only developed a few months ago? Or would you want the materials to be mature and well understood? That's why structural materials can take many years, even decades, to get into real use."

Comments »

If you enjoyed this article, please consider sharing it:

|