17th February 2023 First cultivated beef tenderloin steak A Swiss company has perfected a new technique that allows the cultivation of thick tender steaks.

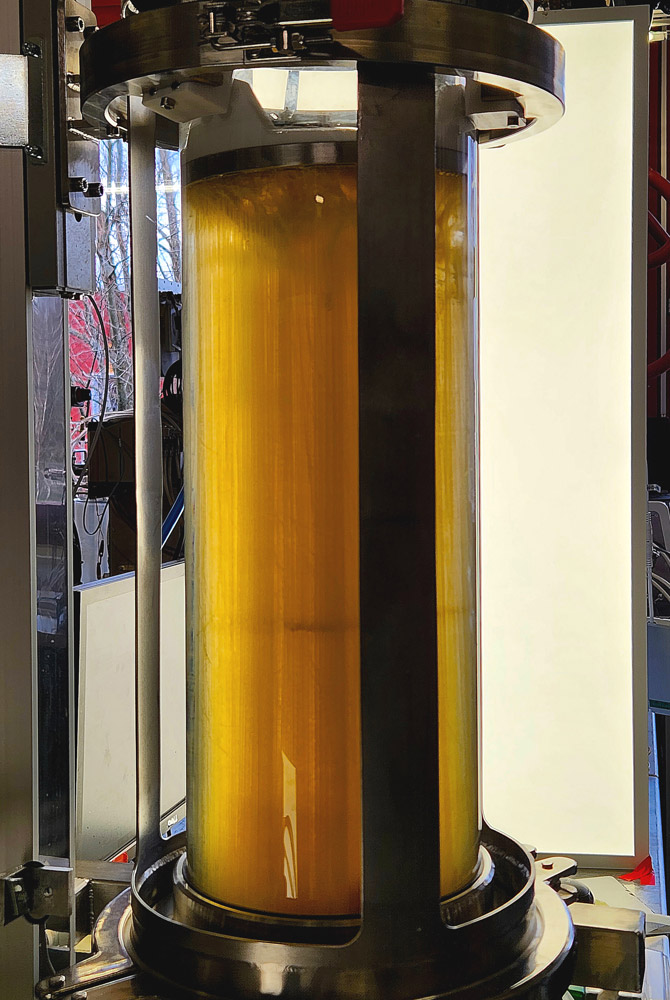

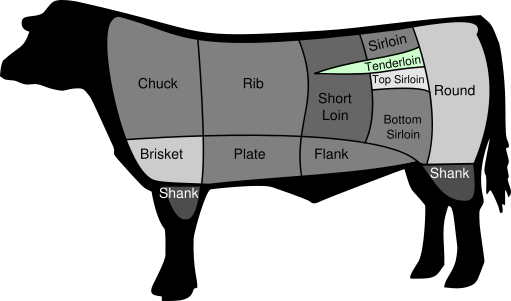

Tenderloin is the softest part of a cow. This muscle – taken from near the animal's backbone – has an almost buttery texture. Highly sought after, this most prized of cuts has a reputation for being the highest priced of all beef types. Attempts to make cultivated (or "lab-grown") tenderloin have been challenging. Previous efforts could only manage very thin slices, or minced meat. However, Swiss startup Mirai Foods announced this week that its 20-person team has succeeded in producing full, thick steaks that are suitable for commercial use. The company has developed what it calls a "Fibration Technology" that enables the efficient cultivation of tissue. This uses 100% natural cells, in a completely GMO-free process. A new bioreactor, known as "The Rocket", embodies the Fibration Technology for which Mirai Foods has filed three patents. Long, fully mature muscle fibres are cultivated inside this, and then combined by enzymes and supplemented with cultivated fat tissue. After five days in the bioreactor, a tenderloin centrepiece is complete, from which steaks of almost any thickness can be cut.

"Other types of meat can already be produced in the lab," says Christoph Mayr, CEO and co-founder. "A fillet steak is the ultimate challenge: it consists of different cell types, which – if combined correctly – result in a complex meat structure. This structuring process is technologically challenging, making steaks extremely difficult to produce. That's why Mirai Foods is taking an important step towards sustainable meat with the first cultivated beef tenderloin steak." "We have filed three international patents for this key technology," says Suman Das, CSO and co-founder of Mirai Foods. "We can deliver a real alternative to conventional meat: Using our technology, one can prepare and eat a real steak – and know that no animal had to die for it and the climate is not harmed. Nutrition is a huge lever for greater climate protection and animal welfare: demand for meat is expected to double by 2050; conventional methods of meat production cannot meet this demand at all, and certainly not in a sustainable way." In the longer term, the company aims to offer a wide range of meat varieties. For now, however, the startup is focusing on premium beef, which has the largest environmental footprint of all meats.

Comments »

If you enjoyed this article, please consider sharing it:

|