16th October 2024 Industrial X-ray scans made 100x faster A breakthrough in 3D X-ray imaging could allow rapid, detailed internal views of products, cutting inspection times by 99% for high-volume manufacturing.

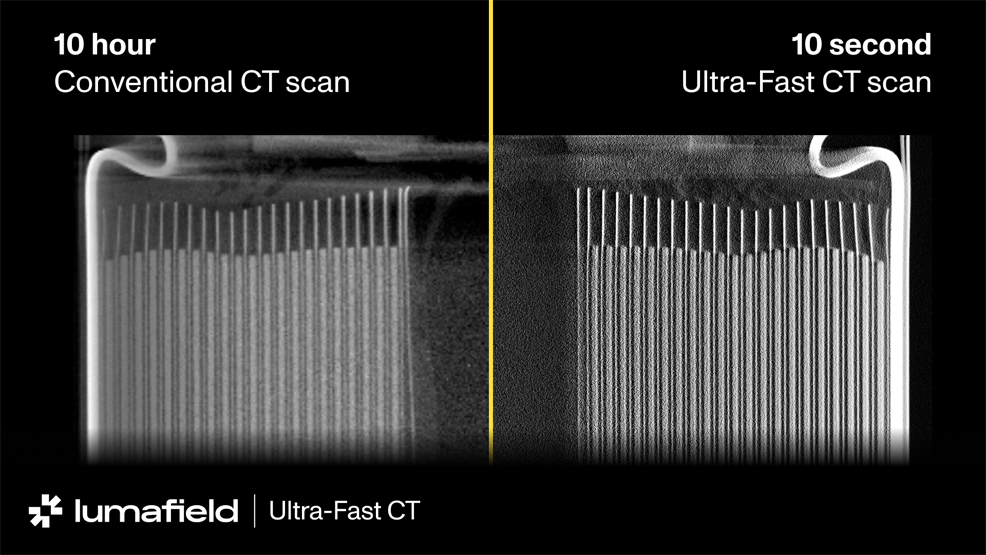

A significant breakthrough in X-ray imaging has been announced by Lumafield. Founded in 2019 and based in Cambridge, Massachusetts, the company is aiming to make industrial computed tomography (CT) more accessible and affordable. Their new Ultra-Fast CT technology captures high-resolution internal scans in as little as 0.1 seconds. While traditional X-ray imaging produces two-dimensional images – commonly used in hospitals and dental surgeries – X-ray computed tomography (CT) creates detailed three-dimensional images by combining multiple X-ray measurements taken from different angles. This allows for a comprehensive examination of both external and internal features of objects, down to the micron level. But while industrial CT generates the most insightful data in manufacturing, its slow speed and high capital equipment costs have prevented widespread adoption at production volumes. Legacy systems entail upfront and ongoing operational expenses upwards of $1 million, keeping this inspection tool out of reach for all but the largest companies. Even for well-resourced engineering organisations, throughput limitations have prevented the widespread adoption of industrial CT for 100% inspection of all parts. CT scanning involves a trade-off between scan time and quality, with faster scans tending to accumulate noise and artifacts that make them less useful. However, Lumafield's new Ultra-Fast CT reduces the amount of scan time required to achieve the same scan quality by more than 100x.

Battery inspection using Ultra-Fast CT. Credit: Lumafield

This breakthrough will be particularly valuable in industries like battery manufacturing for EVs, where ensuring quality and safety is critical. Lithium-ion batteries, such as the one seen in the video above, are high-stakes products: a tiny misalignment between layers, invisible damage during production, or a microscopic contaminant can cause a catastrophic fire. Traditional inspection methods are often too slow or imprecise to catch every issue. Lumafield's technology can provide real-time quality control, reducing the risk of defects and accelerating the deployment of reliable clean energy solutions. Some other areas likely to benefit include medical devices, consumer electronics, and packaging. "Ultra-Fast CT puts you in charge of what you make without compromises or delays," said Eduardo Torrealba, Co-Founder and CEO of Lumafield. "It's about making the right call instantly and taking full control of your production process. We're not just improving inspection with CT scanning – we're revolutionising manufacturing." "At 1/10th of a second, this isn't just an improvement in speed; it's a fundamental shift in how we approach product design," added Andreas Bastian, Co-Founder and Head of Product at Lumafield. "X-ray CT has long been too slow and expensive for production use, but with Lumafield's Ultra-Fast CT, battery manufacturers, packaging suppliers, and medical device manufacturers can finally deploy this technology at massive scales in production."

Comments »

If you enjoyed this article, please consider sharing it:

|

||||||