26th January 2013 Breakthroughs in solar power This month has witnessed a number of breakthroughs in solar power research. Here are some of the more significant developments.

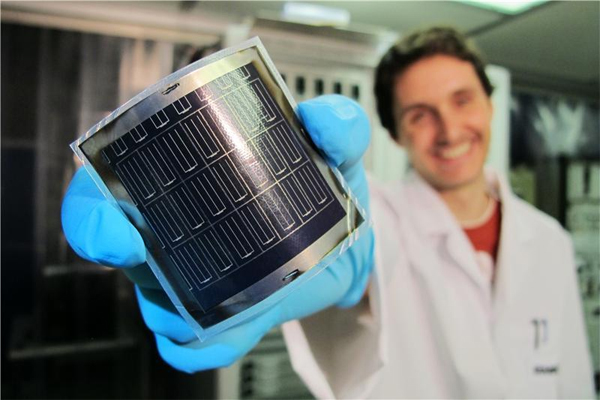

Thin-film solar cells: new world record for efficiency EMPA in Switzerland has developed thin-film solar cells on flexible polymer substrate with a record efficiency of 20.4% for converting sunlight into electricity. This is a significant improvement over the previous record of 18.7% achieved by the same team in May 2011. The cells are based on CIGS (copper indium gallium (di)selenide) and the technology is now awaiting scale-up for industrial uses. Thin-film, lightweight and flexible solar modules are attractive for applications such as roofs and facades of buildings, automobiles and portable electronics. They can be produced using continuous roll-to-roll manufacturing, with panels coming off the assembly line as if from a printing press. This provides further cost reductions compared to standard silicon technologies. Thin-film solar cells were included in TIME's Best Inventions of 2008. Gian-Luca Bona, Director of EMPA: "The series of record efficiencies for flexible CIGS solar cells developed at EMPA demonstrates that thin film solar cells can match the excellent performance of polycrystalline silicon cells. Now it is time for the next step – the scale-up of the technology to cover large areas in a cost-efficient roll-to-roll manufacturing process with an industrial partner."

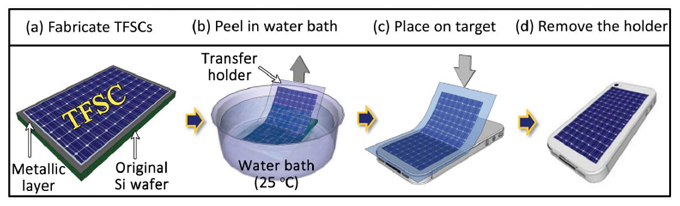

Peel-and-stick solar panels Stanford researchers have succeeded in developing the world's first "peel-and-stick" thin-film solar cells. Unlike standard thin-film solar, this version does not require any direct fabrication on the final carrier substrate. All the challenges associated with putting solar cells on unconventional materials are avoided with this new process, vastly expanding the number of potential applications. The researchers attached their solar cells to paper, plastic and window glass among various other materials, without losing the original cell efficiency. Non-conventional substrates are difficult to fabricate because of their poor surface flatness, along with low tolerance of chemicals and hotter temperatures in the production process. The researchers got around these problems by developing a unique metal "sandwich". The base of this sandwich is formed by a silicon/silicon dioxide wafer. A 300-nanometer film of nickel is deposited on top. Thin-film solar cells are then placed on the nickel layer and covered with protective polymer. Thermal release tape is then attached to the top of the solar cells, to augment their transfer off the production wafer and onto a new substrate. The wafer is submerged in water at room temperature and the edge of the thermal release tape is peeled back slightly, allowing water to seep into and penetrate between the nickel and silicon dioxide interface. The solar cell is thus freed from the hard substrate, but still attached to the thermal release tape. After heating to 90°C, the tape is removed, leaving just the solar cell which can be applied to virtually any surface. Tests prove that the peel-and-stick process leaves the solar cells wholly intact and functional. The silicon wafer base is undamaged and clean after removal, and can be reused for another batch of solar cells. Overall, this new process gives thin-film solar cells a flexibility and attachment potential never seen before – while simultaneously reducing their general cost and weight.

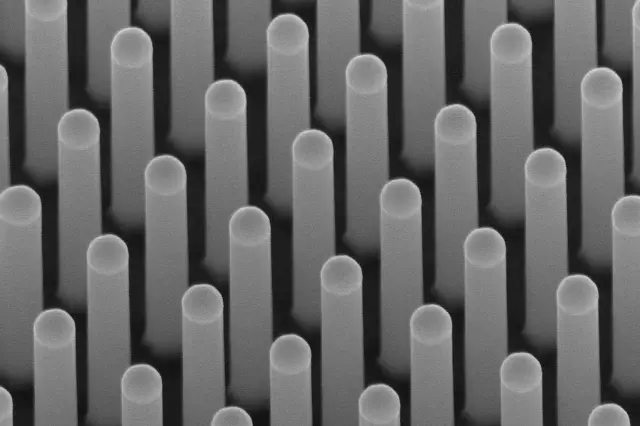

Solar nanowires: ideal diameter identified About 10 years ago, the first generation of solar nanowires began to appear in research labs – arrays of tiny, semiconducting structures able to convert sunlight into energy. Despite their intricacy and compactness, however, performance lagged far behind other technologies. Researchers were unable to attain efficiencies of greater than 10%. This is now changing. Scientists from Lund University in Sweden claim to have identified the ideal diameter for nanowires in solar cells: 180 nanometres. Reporting their study in the journal Science, they show how efficiencies of 13.8% can now be achieved using the semiconductor material indium phosphide. Magnus Borgström, a researcher in semiconductor physics and the principal author: "The right size is essential for the nanowires to absorb as many photons as possible. If they are just a few tenths of a nanometre too small, their function is significantly impaired." The nanowires are shaped like antennae. They are assembled on surfaces of just one square millimetre that each house four million nanowires. This produces an effect per active surface unit several times greater than today's silicon cells. Traditional silicon cells for domestic use are relatively cheap, but inefficient because they only absorb a limited part of the light spectrum, being composed of one single material. Researchers have therefore aimed to combine different types of semiconductor material to utilise a broader part of the spectrum. The disadvantage is that they become extremely expensive and can therefore only be used in niche contexts, such as on satellites or military planes. However, this is not the case with nanowires. Because of their tiny dimensions, the same sort of material combinations can be created with far less effort and complexity, which offers higher efficiency at a lower cost. In the Science article, the researchers have shown that the nanowires can generate power at the same level as a thin film of the same material, even if they cover just one-tenth of the surface. Although still in the laboratory phase, they could eventually be used in large solar power plants.

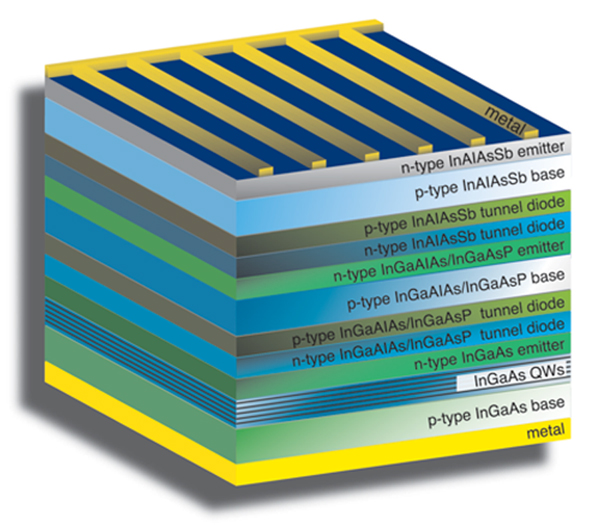

Multi-junction solar cell may break the 50% efficiency barrier As we reported in more detail here, U.S. Naval Research Laboratory scientists, working with Imperial College London and MicroLink Devices, have proposed a novel triple-junction solar cell with the potential to break the 50 percent conversion efficiency barrier, which is the current goal in multi-junction photovoltaic development. At present, the world record for this type of solar power generation is 44 percent under concentration. The researchers believe their technology is "realistically achievable" by 2016.

The U.S. Army's largest solar array installation The largest solar power system in the U.S. Army has come online at White Sands Missile Range, New Mexico, and officials marked the occasion with a ribbon-cutting ceremony. The Energy Savings Performance Contract (ESPC) provides the sprawling desert base with a new 4.5 megawatt solar photovoltaic system, guarantees energy savings of 35,358M British thermal units per year, and cuts energy consumption by 10 percent.

Click to enlarge

Comments »

|