5th February 2018 Robot arms to harvest cucumbers Researchers in Germany are developing a robotic arm and camera system to enable the harvesting of cucumbers at human-level efficiency.

Credit: IPK Fraunhofer

In more and more agricultural settings, automated systems are superseding traditional manual labour. As part of the European Union's (EU) CATCH project, the Fraunhofer Institute for Production Systems and Design Technology (IPK) is developing a dual-arm robot and camera for the automated harvesting of cucumbers and potentially other vegetables. This technology may keep crop cultivation commercially viable in Germany. Cucumbers in Germany are currently harvested by hand with the aid of “cucumber flyers” – pictured below – which are farm vehicles with wing-like attachments. Seasonal workers lie on their stomachs on the vehicle’s wings and pluck the ripe cucumbers. However, this labour-intensive and energy-sapping work is becoming increasingly uneconomical. In addition, per-unit costs of harvesting have risen since Germany introduced a minimum wage of €8.84 ($10.98) per hour. Many of the country’s agricultural regions consequently face an uncertain future; operations have already begun relocating to Eastern Europe and India. There is thus an urgent need for improved technologies to maintain the economic viability of cucumber farming in Germany.

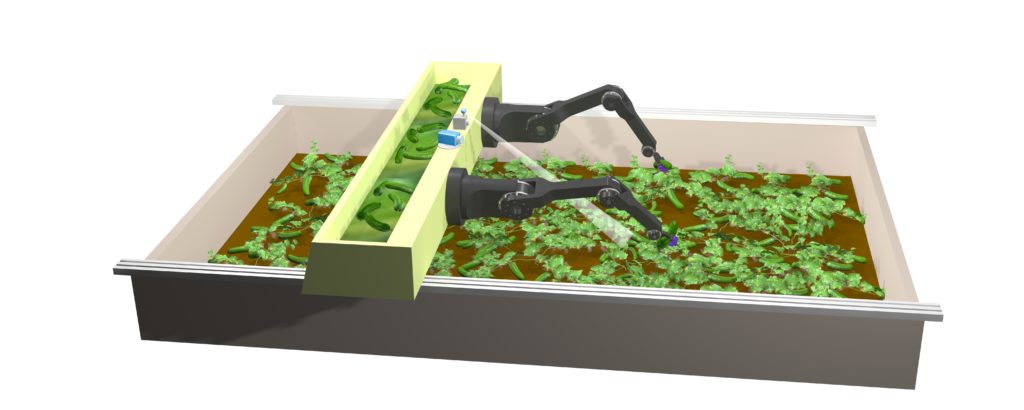

Experts from Fraunhofer IPK in Berlin, alongside other German and Spanish researchers, are studying the potential for automating cucumber harvests in the scope of the EU project CATCH, which stands for “Cucumber Gathering – Green Field Experiments.” Project partners are the Leibniz Institute for Agricultural Engineering and Bioeconomy in Germany and the CSIC-UPM Centre for Automation and Robotics (CAR) in Spain. CATCH researchers want to develop and test a dual-arm robot system consisting of inexpensive lightweight modules. The ultimate aim: a system that could be used for automated cucumber farming and other applications. The robotic picker needs to be cost-effective, high-performance and dependable. Even in adverse weather conditions, it must be capable of identifying ripe cucumbers and then using its gripper arms to gently pick and store them. To this end, cutting-edge control methods will equip the robot with tactile perception and enable it to adapt to ambient conditions. These technologies will ensure that the dual-arm robot system can imitate human movements and avoid damage to crops – while being at least as efficient as an experienced human, who can pick as many as 13 cucumbers per minute. Designing an autonomous system with optical and tactile sensing, capable of judging and lifting vegetables, is a considerable challenge. The robot must identify green objects that are camouflaged by green surroundings, randomly distributed throughout a field, some concealed by vegetation and in varying light conditions. The CATCH team plans to use multispectral cameras and intelligent image processing to help spot cucumbers and guide the robot’s arms to grip and pluck them. They have developed robotic arms with five degrees of freedom. Their current prototype (pictured below) can detect and locate approximately 95% of cucumbers – an impressive success rate. The goal, of course, is to advance the technology so the robot picks all the ripe cucumbers to foster growth of new ones.

Dr. Dragoljub Surdilovic, a scientist at Fraunhofer IPK: “The robot can push leaves to the side using symmetrical or asymmetrical movements, or congruent and incongruent movements. As a result, it can automatically change directions on the fly to approach and then grasp a cucumber.” The Leibniz Institute for Agricultural Engineering and Bioeconomy in Potsdam, Germany, has used various types of cucumbers to conduct initial field testing of the system at its test site. In short, the first round of testing validated basic functionality. Since fall 2017, project partners have been conducting additional trials in a Leibniz Institute greenhouse. Researchers are especially eager to scrutinise the extent to which interference or malfunctions affect the efficiency and robustness of the system. Once testing of the machine has been completed, project partners will strive to make it commercially viable. Companies, cucumber farmers and agricultural associations have expressed considerable interest in the dual-arm robot. In November 2017, the project was unveiled to the general public at Agritechnica, the world’s leading trade fair for agricultural technology. The German Agricultural Society exhibited the robot at its Agritechnica booth, eliciting positive feedback from agricultural specialists and numerous companies.

Comments »

If you enjoyed this article, please consider sharing it:

|