21st August 2018 New alloy is 100 times more durable than high-strength steel A team at Sandia National Laboratories in the U.S. has engineered a platinum-gold alloy believed to be the world's most wear-resistant metal. The material is 100 times more durable than high-strength steel, making it the first alloy (combination of metals) in the same class as diamond and sapphire – nature's most wear-resistant materials. “We showed there’s a fundamental change you can make to some alloys that will impart this tremendous increase in performance over a broad range of real, practical metals,” said materials scientist Nic Argibay, an author on the paper. Although metals are typically thought of as strong, when they repeatedly rub against other metals – as happens in engines – they wear down, deform and corrode unless they have a protective barrier, like additives in motor oil. In electronics, moving metal-to-metal contacts receive similar protections with outer layers of gold or other precious metal alloys. However, these coatings are expensive. And eventually they wear out, too, as connections press and slide across each other day after day, year after year – sometimes millions, even billions of times. These effects are exacerbated the smaller the connections are, because the less material you start with, the less wear and tear a connection can endure before it no longer works. With Sandia's new material, a hypothetical car with tires made from the alloy could skid – not drive, but actually skid – around Earth's equator 500 times before wearing out the tread. After a mile of skidding, only a single layer of atoms would be lost.

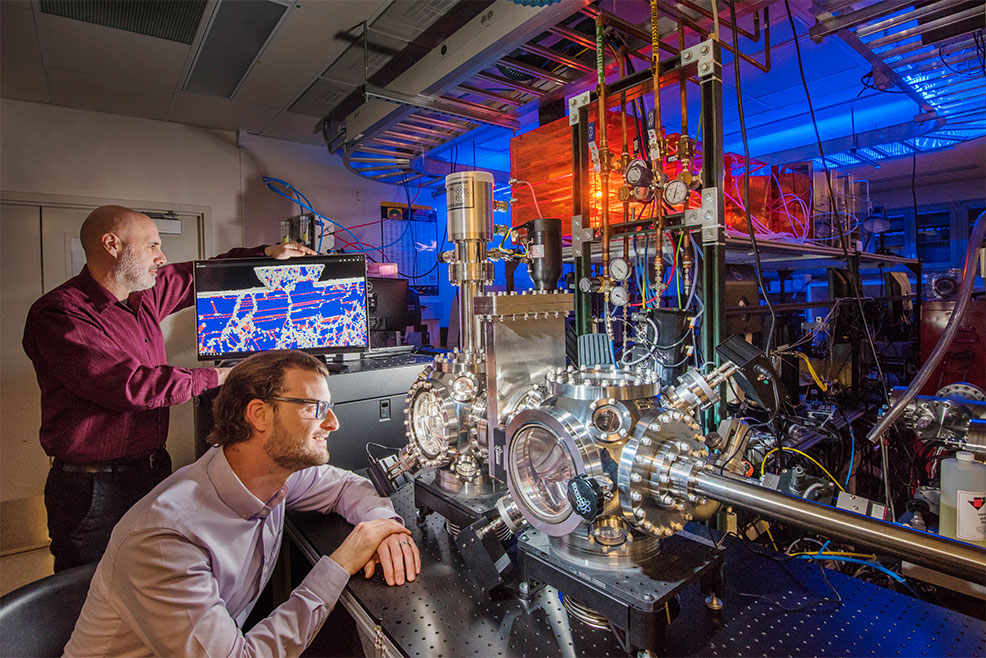

The ultradurable coating could save the electronics industry more than $100 million a year in materials alone, says Argibay, and make electronics of all sizes and across many industries more cost-effective, long-lasting and dependable – from aerospace systems and wind turbines, to microelectronics for cell phones and radar systems. “These wear-resistant materials could potentially provide reliability benefits for a range of devices we have explored,” said Chris Nordquist, a Sandia engineer not involved in the study. “The opportunities for integration and improvement would be device-specific, but this material would provide another tool for addressing current reliability limitations of metal microelectronic components.” The team's breakthrough emerged from simulations that calculated how individual atoms were affecting large-scale properties of the metal, a connection that is rarely obvious from observations alone. “We're getting down to fundamental atomic mechanisms and microstructure and tying all these things together to understand why you get good performance or why you get bad performance, and then engineering an alloy that gives you good performance,” said co-author Michael Chandross. The team recently published their findings in the journal Advanced Materials.

Comments »

If you enjoyed this article, please consider sharing it:

|