10th February 2023 Breakthrough in recycling of wind turbine blades A new chemical process developed by Danish company Vestas can ensure that wind turbine blades are recycled at the end of their life, instead of being abandoned or going to landfill sites.

Wind power is one of the best ways to decarbonise the world's electricity. Recent years have seen explosive growth in capacity additions, as well as gigantic new turbine designs able to generate as much as 18 MW. The costs keep falling, while efficiencies continue to improve. The trend is now obvious: renewable energy is the future and will inevitably displace fossil fuels. But ironically, wind power is now itself in danger of becoming unsustainable. Despite being clean, the lifespan of wind turbines is finite, generally in the region of 20 to 25 years. After decades of wear and tear, old turbines from the late 1990s and early 2000s are now reaching the end of their working lives, with many blades piling up in landfills and other sites. Since the number of installations has been growing exponentially, this has the potential to become a big problem in terms of waste management. Already, an estimated 8,000 units in the U.S. and 14,000 in Europe are decommissioned each year. Finding a way to recycle these blades has been challenging, due to the chemical properties of epoxy resin – a highly resilient substance, previously thought to be impossible to break down into re-usable components. The industry has attempted to replace or modify epoxy resin with alternative materials that can be more easily treated. Meanwhile, deniers of human-caused climate change have often used this physical disadvantage of turbine blades as an argument against the transition to renewable energy. Vestas, headquartered in Denmark, is the world's largest installer of turbines, having deployed 160 GW of wind power in 88 countries. The Danish company has just announced a breakthrough solution for epoxy-based turbine blades, which can make them part of a circular economy, without the need for changing the design or composition of blade material.

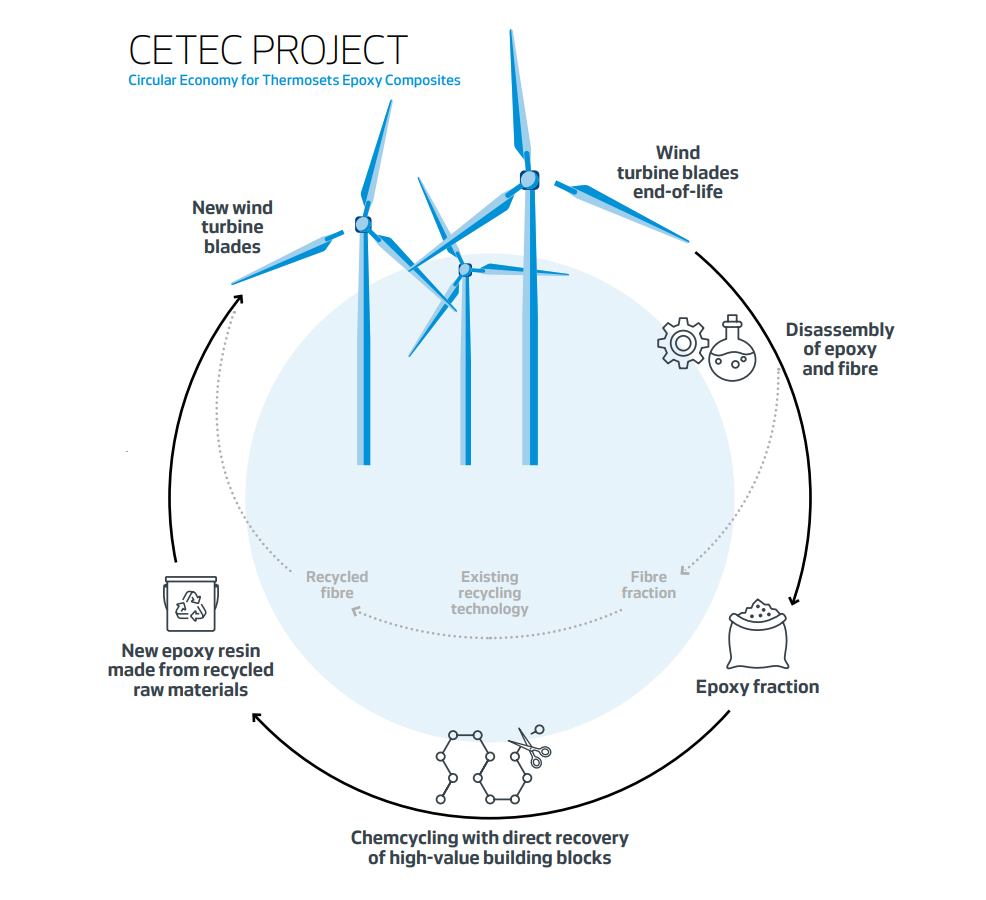

Vestas' solution is enabled by a novel chemical process that can break down epoxy resin into virgin-grade materials. It has been developed in collaboration with Aarhus University, the Danish Technological Institute, and Olin, as part of the CETEC project (Circular Economy for Thermosets Epoxy Composites), which is bringing together industry and academia to investigate recycling technology for turbine blades. Through a newly established value chain – supported by Nordic recycling leader Stena Recycling and global epoxy manufacturer Olin – Vestas will now focus on scaling up its chemical disassembly process into a commercial solution. Once mature, it will mean the beginning of a circular economy for all existing, and future epoxy-based turbine blades. "The newly discovered chemical process shows that epoxy-based turbine blades, whether in operation or sitting in landfill, can be turned into a source of raw material to build new turbine blades," says Mie Elholm Birkbak, a research specialist at Vestas, who holds a PhD in nanoscience from Aarhus University. "As the process relies on widely available chemicals, it is highly compatible for industrialisation, and can therefore be scaled up quickly. This innovation would not have been possible without the ground-breaking CETEC collaboration between industry and academia enabling our progress until this point." "In the coming years, thousands of turbines will be decommissioned or repowered – representing a major sustainability challenge, but also a valuable source of composite materials," says Henrik Grand Petersen, MD of Stena Recycling Denmark. "As one of Europe's leading recycling groups with a wide footprint in Europe, we have a central role in the transition to a circular economy. We see this solution as a huge opportunity to take part in making a sustainable solution even more sustainable and circular and are ready to apply our chemical recycling expertise and knowledge to this process." "As the leading customer solution provider of innovative epoxy systems, Olin is proud to support the anticipated massive expansion in wind energy worldwide," says Verghese Thomas, Vice President, Epoxy Systems and Growth Platforms at Olin. "By utilising unique technologies, together with our partners, we are ready to recover molecules and convert them into new epoxies that can be re-used in wind turbine blades. We are excited to bring our expertise and unique asset footprint to this partnership, and realise breakthrough sustainable material solutions, both for existing wind blades and those of the future."

Comments »

If you enjoyed this article, please consider sharing it:

|