9th February 2023 CO2 from direct air capture stored in concrete For the first time, direct air capture (DAC) has been combined with permanent storage of carbon dioxide (CO2) in concrete. This technology could be vital to reducing the climate impacts of the world's building stock, which may double by 2060.

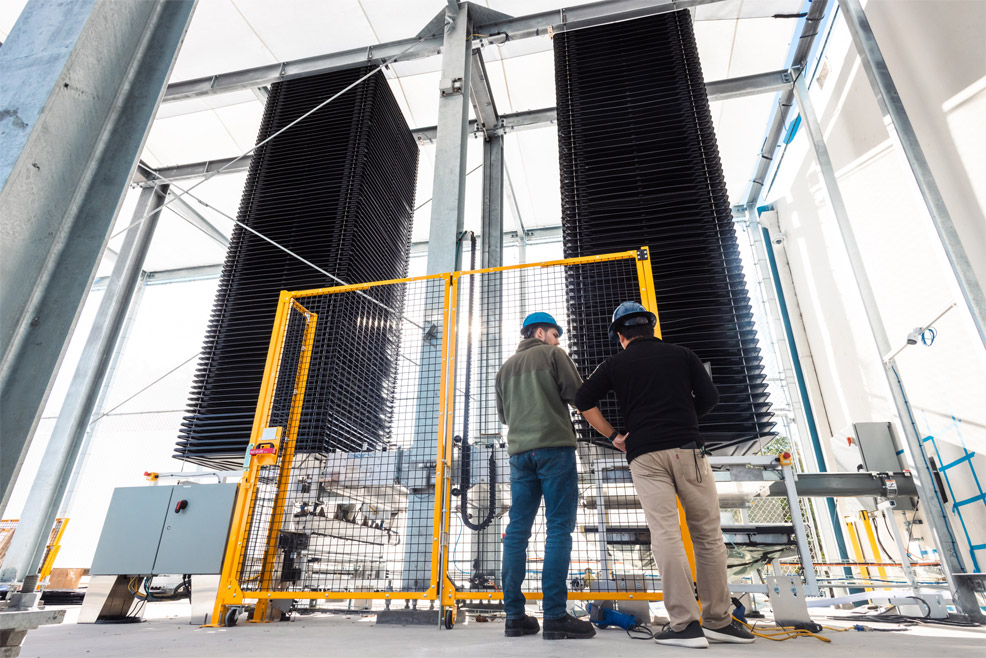

Three companies – Heirloom, CarbonCure Technologies, and Central Concrete – have collaborated on a system that can extract CO2 from the atmosphere and then convert it to "green concrete" for use in constructing homes, hospitals, schools, and other infrastructure. If scaled up, the new process could help to permanently store gigatons of carbon emissions around the world. For this demonstration, Heirloom captured CO2 from the atmosphere using DAC technology at their HQ in Brisbane, California. The second company, CarbonCure, used its reclaimed water technology to inject the CO2 into process wastewater at a batch plant in San Jose, California. Central Concrete used the CO2-treated wastewater to make fresh concrete for a range of projects around the Bay Area. Heirloom runs the only operational DAC facility in America. It uses calcium hydroxide, crushed and spread onto vertically-stacked trays – as pictured below – which acts like a sponge, binding with CO2 from the atmosphere to form calcium carbonate. This limestone mineral powder is then heated in a renewable-energy powered electric kiln to remove the CO2.

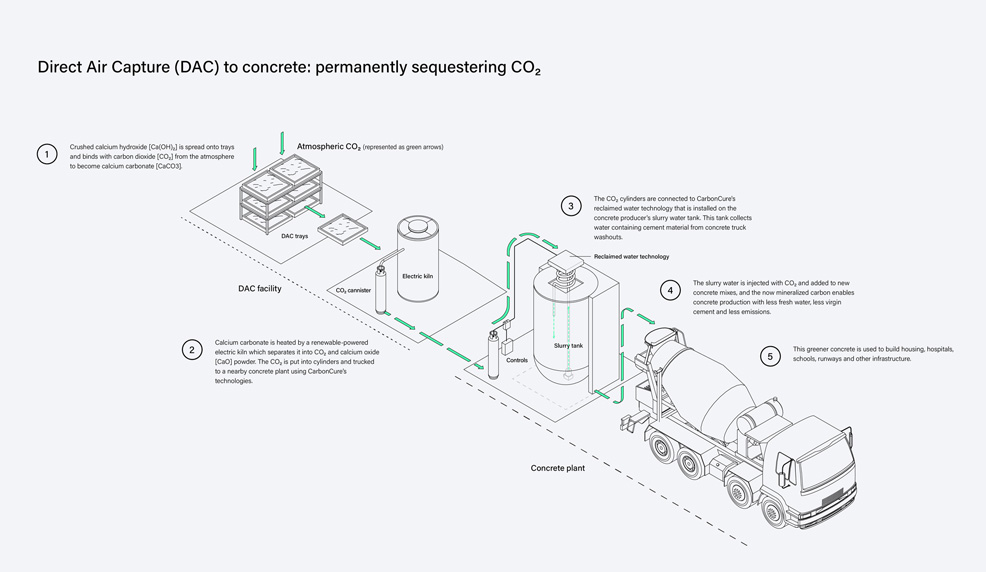

As shown in the diagram below (click to enlarge), the CO2 is placed in cylinders and trucked to CarbonCure's nearby facility. The cylinders are connected to a reclaimed water system and slurry tank. The slurry water is injected with CO2 and added to new concrete mixes. The now mineralised carbon enables concrete to be produced with less fresh water, less virgin cement, and lower emissions. The CO2 is durably sequestered within the concrete in the form of calcium carbonate and will not be returned to the atmosphere for thousands of years, even if the concrete is demolished. It retains the same strength and qualities as traditional concrete. For this demonstration, only 38 kg (84 lbs) of captured CO2 went into the finished concrete. To put things in perspective, cement is responsible for 7% of the world's annual CO2 emissions, or 2.6 billion tonnes each year. Added to which, the global building stock is likely to double by 2060 – the equivalent of building another New York City every month for the next 40 years. Clearly, the process has a long way to go before it can make a significant dent in global emissions. These days, however, new technologies can often progress by orders of magnitude in a relatively short time – as we are seeing now with solar, wind, EVs, and batteries, for example. Green concrete may soon join that list of disruptive industries with vast potential for scaling up. Heirloom is hopeful that limestone could remove 1 billion tons of CO2 by 2035. "The science is clear – in order to reach our climate goals, we must remove billions of tonnes of already emitted CO2 from the atmosphere each year," said Shashank Samala, CEO of Heirloom. "This is an important step toward that future and shows the promise of DAC technologies combined with smart, permanent methods of sequestration." "This demonstration project is a global milestone for carbon removal technology, which confirms concrete's enormous potential as a climate solution that can permanently store carbon in our most essential infrastructure – from roads and runways to hospitals and housing," said Robert Niven, Chair and CEO of CarbonCure Technologies. "We're thrilled to be collaborating with Heirloom and Central Concrete on this groundbreaking world first."

Click to enlarge

Comments »

If you enjoyed this article, please consider sharing it:

|