18th May 2024 Heat from solar energy could decarbonise heavy industry Solar energy has been combined with synthetic quartz to generate temperatures of more than 1,000 °C. This proof-of-concept method shows the potential of clean energy to replace fossil fuels in heavy manufacturing.

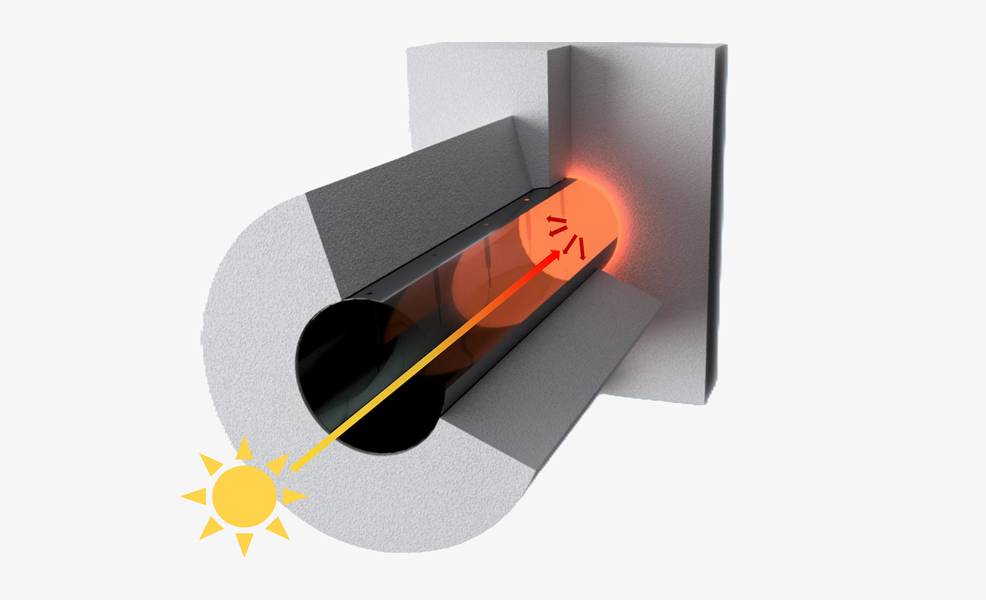

Today, the heat necessary to smelt steel and cook cement requires burning fossil fuels. But researchers in Switzerland are developing a more sustainable method using heat from the Sun. In their study – appearing this week in the journal Device – a team from public research university ETH Zurich has demonstrated the use of synthetic quartz to trap solar energy at 1,050 °C (1,922 °F). If their prototype is developed further, it has potential to generate clean energy for carbon-intensive industries, according to the scientists. "To tackle climate change, we need to decarbonise energy in general," says Emiliano Casati, PhD, from the Department of Mechanical and Process Engineering at ETH Zurich. "People tend to only think about electricity as energy, but in fact, about half of the energy is used in the form of heat." Glass, steel, cement, and ceramics are at the heart of modern civilisation, essential for building everything from car engines to skyscrapers. These industries together account for about 25% of global energy consumption. Researchers have previously explored using solar receivers, which concentrate and build heat with Sun-tracking mirrors, as a clean energy alternative. However, this technology has difficulties transferring solar energy efficiently above 1,000 °C. To boost the efficiency of solar receivers, Casati turned to semi-transparent materials such as quartz, which can trap sunlight – a phenomenon known as the thermal‑trap effect. His team crafted a thermal-trapping device by attaching a synthetic quartz rod to an opaque silicon disk as an energy absorber. When they exposed the device to an energy flux equivalent to the light coming from 136 suns, the absorber plate reached 1,050 °C (1,922 °F), whereas the other end of the quartz rod remained at 600 °C (1,112 °F).

"Previous research has only managed to demonstrate the thermal-trap effect up to 170 °C (338 °F)," says Casati. "Our research showed that solar thermal trapping works not just at low temperatures, but well above 1,000 °C. This is crucial to show its potential for real-world industrial applications." Using a heat transfer model, the team also simulated the quartz's thermal-trapping efficiency under different conditions. The model showed that thermal trapping achieves the target temperature at lower concentrations with the same performance, or at higher thermal efficiency for equal concentration. For example, a state-of-the-art (unshielded) receiver has an efficiency of 40% at 1,200 °C, with a concentration of 500 suns. The receiver shielded with 300 mm of quartz achieves 70% efficiency at the same temperature and concentration. The unshielded receiver requires at least 1,000 suns of concentration for comparable performance. Casati's team is now optimising the thermal-trapping effect and investigating new applications. Their follow‑up research has been promising. By exploring other potential materials, such as different fluids and gases, they have already reached even higher temperatures. The team also notes that these semi‑transparent materials' ability to absorb light or radiation is not limited to solar radiation. "The energy issue is a cornerstone to the survival of our society," adds Casati. "Solar energy is readily available, and the technology is already here. To really motivate industry adoption, we need to demonstrate the economic viability and advantages of this technology at scale."

Comments »

If you enjoyed this article, please consider sharing it:

|

||||||