2nd July 2023 Carbon capture made simpler and cheaper A new method of direct air capture (DAC) developed at the Georgia Institute of Technology uses ambient wind flow, drawn across sorbent-coated carbon fibres. If scaled up, the system could slash the cost of capturing carbon dioxide (CO2) to as low as $150 per ton.

As the world continues to warm, driven by human emissions of CO2 and other heat-trapping greenhouse gases, the need to decarbonise our way of life becomes ever more urgent. Renewable energy, electric transportation, energy-efficient buildings, and other green technologies can help in this transition. But given how little time remains before the passing of climate tipping points, even zero-carbon energy and ubiquitous electrification may prove insufficient. Keeping the global average temperature rise below a safe level will almost certainly require the use of "net negative" solutions too. One of the most promising forms of net-negative technology is direct air capture (DAC). This works by pulling in atmospheric air, then using chemical processes to selectively remove CO2. The captured gas can then be stored underground or used in various industrial applications. DAC offers the potential for large-scale CO2 removal without requiring large areas of land like some bioenergy strategies. Moreover, it can be deployed anywhere in the world, adding to its flexibility. Since it remains in the early stages of development and has yet to become a mature industry, DAC is an expensive and energy-intensive process. However, innovative concepts are being worked on, which could soon pave the way to rapid improvements in cost and efficiency, much like the exponential trends in solar and wind power that have occurred in recent decades. If these new systems could be perfected and scaled up, it might be possible to remove megatons of CO2 each year by the 2030s and even gigatons during the 2040s. A significant fraction of legacy emissions from past decades and centuries would then be taken out of the climate system, avoiding a scenario of unstoppable global heating – while also improving air and water quality. One of the latest ideas for DAC is published this month in the prestigious journal Joule, appearing as its cover story. The new concept is presented by researchers from the Georgia Institute of Technology.

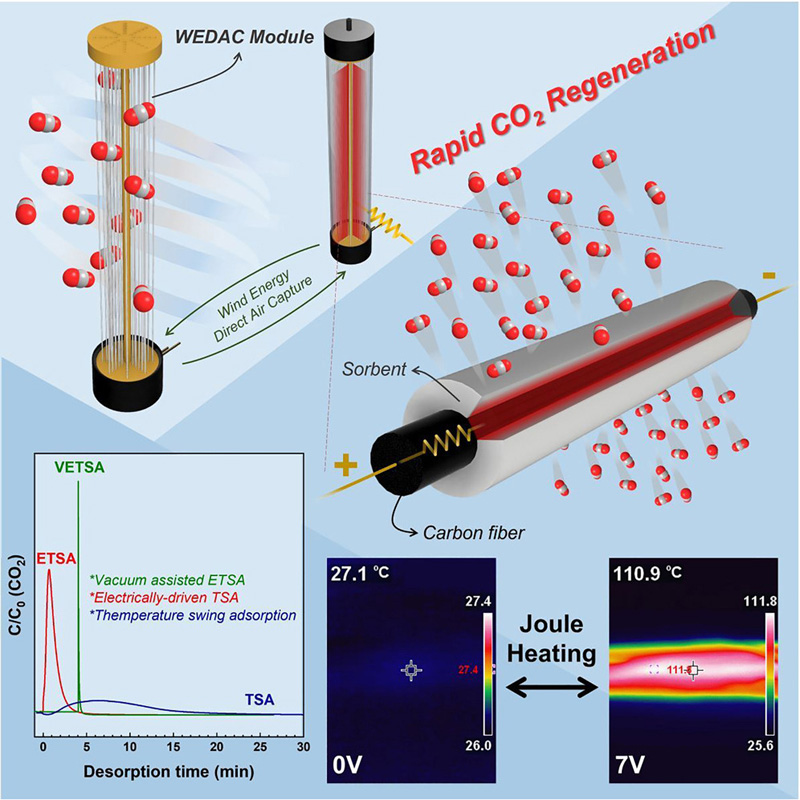

The device aims to simplify traditional DAC systems. It uses ambient wind flow to draw air across a new kind of coated carbon fibre, grabbing CO2 in the process. This has two major advantages: it eliminates the loud and bulky fans used in current systems; and the carbon fibre strands can be quickly heated to release the captured CO2 with minimal heat loss, boosting efficiency. Typical DAC systems use external heating sources, like steam, to release captured CO2 from saturated filter materials. The CO2 can then be stored underground or used to make chemicals. However, such systems are bulky, expensive, and involve a condensing step, as well as insulation to prevent heat from escaping. The team at Georgia Tech have radically improved this process by using carbon fibre strands coated with a sorbent that heats from the inside, providing fast and even heat distribution. The design is simpler overall, using fewer components and reducing the upfront cost. It eliminates the need for steam generators, pumps, and condensers to remove the CO2 and recharge the strands. The modules are deployed in a circle to capture CO2 no matter which way the wind blows.

The rapid heating and fast cycling of the system holds great promise for a more productive and efficient approach to direct air capture. Ideally, the system could be situated alongside a wind farm, using renewable energy from wind turbines. But even using power from the current grid, analysis shows that it would still remove enough CO2 from the atmosphere to be carbon negative. The materials in each module are readily available, can be sustainably manufactured in large quantities, and are not prohibitively expensive. The team has used experimental data to project the economics of a practical system. They found that their new design could capture CO2 for $150 to $200 per ton – much less than commercial systems under construction that typically range from $300 to $600 per ton. "This work not only conceptualised a new generation of DAC systems but also showed practical operations of our invention to some extent," said Won Hee Lee, research engineer and study first author. "We already successfully captured ambient CO2 with our lab-scale module. Now it's important to scale up the module. Since all the components of our system are commercially available and fabrication is relatively easy, there should be few technical hurdles to making the module in large scale."

Comments »

If you enjoyed this article, please consider sharing it:

|