27th December 2025 A new plant-based plastic that vanishes in seawater Japanese researchers have created a tough, flexible plastic made from plant cellulose that breaks down quickly and safely in salt water. Unlike most "biodegradable" plastics, it leaves behind no microplastics.

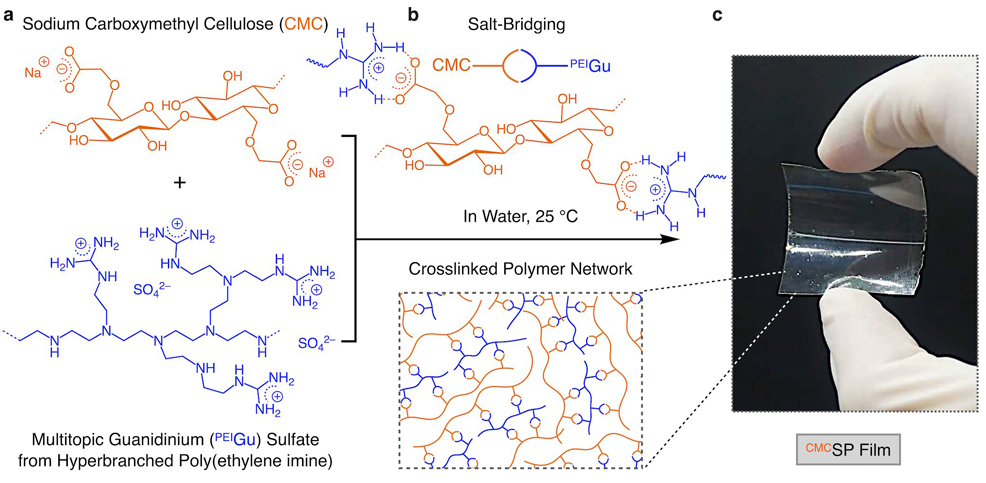

Microplastics now contaminate almost every part of the planet. Scientists have found them in oceans, soils, wildlife, and even in human blood and tissues, where researchers suspect they may cause harm. Although manufacturers often label plastics as biodegradable, most of these materials either fail to truly break down in marine environments or degrade so slowly that they shed microplastics along the way. A research team led by Professor Takuzo Aida at the RIKEN Center for Emergent Matter Science (CEMS) in Japan now reports a promising alternative. Writing in the Journal of the American Chemical Society, the researchers describe a new type of plastic made primarily from plant cellulose, the most abundant organic material on Earth. The plastic combines strength and flexibility with a rare property: it rapidly falls apart in salt water without producing microplastics. This work builds on an earlier breakthrough from Aida's group. Last year, his team developed a supramolecular plastic that dissolved within hours in seawater. That material relied on reversible chemical links known as "salt bridges". When exposed to salt water, these links broke apart and caused the plastic to disintegrate. However, the original material proved difficult to manufacture at scale, limiting its practical use. The latest version replaces one of the original components with carboxymethyl cellulose, a biodegradable wood-pulp derivative already approved for use in food and pharmaceuticals. The team then searched for a compatible second component and identified a safe crosslinking agent made from positively charged polyethylene-imine guanidinium ions. When mixed in water at room temperature, the negatively charged cellulose chains and positively charged ions attracted each other like magnets, forming a strong internal network. In salt water, the same network quickly came apart, allowing the plastic to dissolve as intended.

To prevent the material from degrading too early, manufacturers can protect it with a thin surface coating. This approach allows the plastic to function normally during use but break down when it reaches the ocean. A previous version of the material revealed another challenge. Cellulose made the plastic extremely hard but also brittle, giving it a glass-like tendency to crack. To solve this, the team searched for a suitable plasticiser – some small molecule they could add to the mix to make the plastic more flexible, yet remain hard. After much experimenting, they eventually found an effective solution with choline chloride, an organic salt commonly used as a food additive. By adjusting the quantity of choline chloride, the researchers could precisely control the plastic's flexibility. At one extreme, it behaved like rigid glass. At the other, it stretched to 130% of its original length without breaking. The team even produced transparent films as thin as 0.07 millimetres. Professor Aida says the breakthrough marks a shift from theory to application. "Our initial study focused mainly on proving the concept," he explains. "This work shows that the material is now practical." The new carboxymethyl cellulose supramolecular plastic, known as CMCSP, matches the strength of conventional petroleum-based plastics while remaining transparent, recyclable, and fully degradable in seawater. Because the ingredients are inexpensive and already approved for use, the researchers believe the technology could reach real-world applications quickly. "Nature produces about one trillion tonnes of cellulose every year," says Aida. "From this abundant resource, we have created a flexible yet tough plastic material that safely decomposes in the ocean. This technology will help protect the Earth from plastic pollution."

Video credit: Chen et al., Journal of the American Chemical Society (2025)

Comments »

If you enjoyed this article, please consider sharing it:

|

||||||