1st January 2026 Breakthrough in space-based manufacturing British aerospace company Space Forge has reported a major milestone in orbital semiconductor production, potentially enabling materials with 4,000 times fewer defects than those made on Earth.

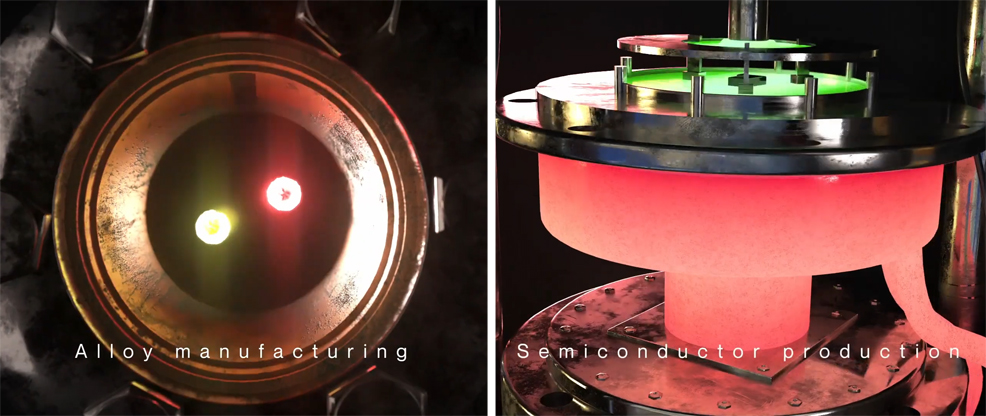

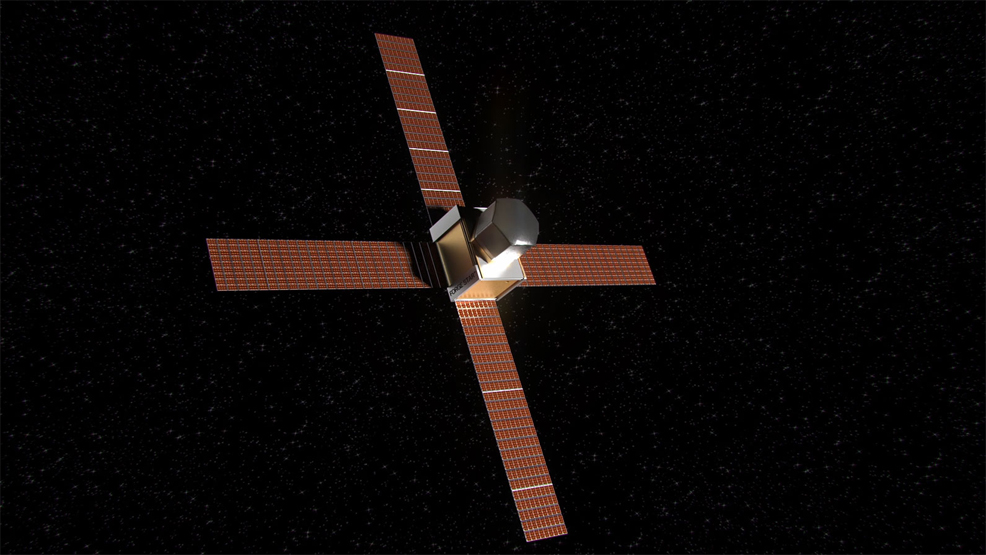

For decades, researchers have studied how manufacturing processes behave in space, inspired by the unique advantages of microgravity, ultra-clean vacuums, and stable thermal environments. This work has generally taken the form of scientific experimentation, rather than sustained production, typically conducted on government-funded platforms such as the Space Shuttle, Mir, and later the International Space Station (ISS), or during short-duration microgravity missions. That picture now seems to be changing, as commercial spacecraft begin to demonstrate the ability to initiate complex industrial processes independently in orbit. UK company Space Forge has reached a major milestone in this emerging field by successfully generating plasma aboard its ForgeStar-1 satellite. This marks a world-first for private in-space manufacturing and confirms that the extreme conditions required for advanced crystal growth can now operate on a free-flying, autonomous platform in low Earth orbit. Space Forge launched ForgeStar-1 in June 2025 aboard a SpaceX Falcon 9 rideshare mission, placing the UK's first dedicated orbital manufacturing satellite into low Earth orbit (LEO). The spacecraft – ten times larger than an earlier prototype – has since operated independently as a compact micro-factory, running a sequence of preparatory tests ahead of its high-temperature furnace activation. This builds on earlier research carried out aboard the International Space Station, but it represents the first time a dedicated commercial spacecraft has demonstrated such capability on its own platform. By generating and controlling plasma, Space Forge has shown that gas-phase crystal growth, a core step in semiconductor production, can take place beyond Earth's gravity and without human intervention. Yesterday, the company announced that its furnace had reached a crucial temperature of 1,000 °C (1,832 °F).

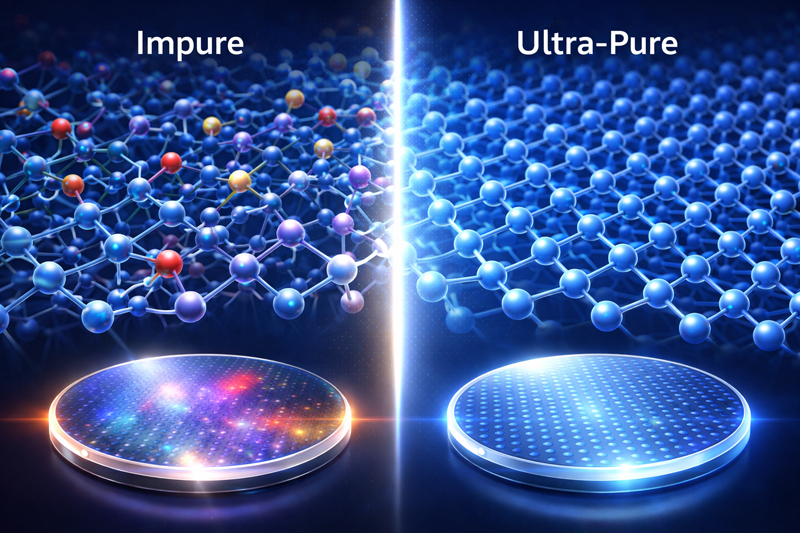

Space Forge frames its long-term business model as offering "microgravity as a service", enabling customers to access orbital conditions that remain impossible to replicate on Earth. The company focuses on wide- and ultra-wide bandgap materials – specialised semiconductors that can operate at far higher voltages, temperatures, and power levels than conventional silicon – including gallium nitride, silicon carbide, aluminium nitride, and diamond. These materials underpin technologies such as power electronics, advanced communications, quantum systems, defence platforms, and high-performance computing. On Earth, manufacturers struggle to produce them without defects, impurities, and thermal instability during growth, all of which limit efficiency and long-term reliability. Low Earth orbit provides an environment that changes this process in fundamental ways. In microgravity, the lack of buoyancy prevents hot liquids from rising and heavy elements from sinking, allowing molten materials to solidify into smoother, more perfect structures. Additionally, the vacuum of space can allow for cleaner processing environments if shielded from atomic oxygen, while the infinite heat sink of deep space allows rapid and precise temperature control not easily achievable on Earth. According to Space Forge, these factors could reduce defects by orders of magnitude: a profound advance in materials science.

Joshua Western, CEO and co-founder of Space Forge, notes the significance of the result: "Generating plasma on orbit represents a fundamental shift. It proves that the essential environment for advanced crystal growth can be achieved on a dedicated, commercial satellite, opening the door to a completely new manufacturing frontier." ForgeStar-1 now enters its next phase, as the mission team studies how plasma behaves in microgravity by running controlled experiments in LEO. Engineers will use the resulting data to refine the design and operation of future missions and to better understand how orbital conditions translate into real performance gains in finished materials. As the spacecraft begins its natural orbital decay, the team will also perform a controlled end-of-life manoeuvre, supported by the Science and Technology Facilities Council. This carefully planned conclusion aims to demonstrate safer satellite disposal and lay the groundwork for future reusable and returnable manufacturing missions. Looking further ahead, Space Forge plans to combine orbital production with terrestrial processing, creating a hybrid manufacturing model that aims to complement existing supply chains rather than replace them. The company is already planning a larger orbital factory, designed to produce enough semiconductor material for tens of thousands of advanced chips, as it moves from demonstration toward early commercial scale. Future missions will place greater emphasis on recovery and reuse. Space Forge intends to deploy a dedicated heat shield, named Pridwen, to protect spacecraft during atmospheric re-entry, allowing processed materials to return safely to Earth for further refinement. Alongside its technical ambitions, the company has pointed to broader economic implications, arguing that in-space manufacturing could eventually reduce costs, improve efficiency and performance across a wide range of industries, and lower environmental impacts. Industry forecasts cited by Space Forge suggest the sector could grow rapidly over the next decade, potentially reaching a market value of around $21.8 billion by 2032 if the technology scales successfully.

Comments »

If you enjoyed this article, please consider sharing it:

|

||||||